Flexible Leiterplatten

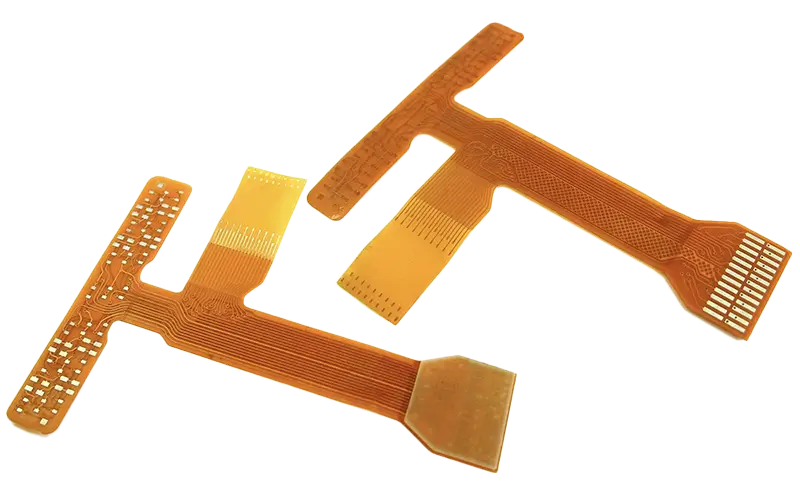

Leiterplatten aus dünnen flexiblen Folien sind ideal zur Bewältigung komplexer geometrischer Aufgabenstellungen. Sie bieten viel Freiraum bei der Konstruktion. Geringer Platzbedarf, niedriges Gewicht und Reduzierung der Systemkosten durch Einsparung von Kabeln und Steckverbindern in der Gerätemontage sind nur einige der Vorteile.

Möglichkeiten mit flexiblen PCBs

Flexible Leiterplatten, auch als FPCs (Flexible Printed Circuits) bekannt, ermöglichen elektronische Komponenten in dreidimensionalen Konfigurationen zu platzieren, was in Anwendungen wichtig ist, bei denen Platz und Formfaktor kritisch sind.

Das flexible Substratmaterial, meist Polyimid (Kapton), erlaubt die Leiterplatte zu biegen und – mit geringstem Biegeradius – zu falten. Die benötigten Größen reichen von sehr kleinen und schmalen Flexen von <1 mm Größe bis zu großen und langen Anwendungen, die dann als Langflex mit mehreren Metern Länge gefertigt werden.

Auch die Konstruktionsmöglichkeiten sind vielfältiger als bei anderen Technologien: Neben einlagigen und zweilagigen FPC mit und ohne Stiffener gibt es flexible Multilayer meist mit Schirmlagen, mit Impedanzen, mit Kontaktierung von einer Seite, aus Hochtemperaturmaterial und mit vielem mehr.

Unsere Materialien, Technologien und Toleranzen

Maximale Größe

470 × 575

mm

Basiskupfer

9–140

µm

Basisfolien

12–150

µm

Aufbau-Varianten

kleberlos oder kleberhaltig

Bis zu

14

Lagen

Im Einsatz in

DLR / NASA / ESA

Projekten

Add Ons

- Stiffener

- ZIF-Stecker

- Hartgoldkontakte

- Klebefolien

- Aufgefächert

- Zweiseitiger Zugriff

- Stabile THT-Lötfinger

- Heizstrukturen

- Heatsinks

Für Ihre individuellen Detailplanungen steht ANDUS Ihnen mit Auslegungsempfehlungen und Layout-Service gerne zur Verfügung.

Einige Referenzen

Miniaturisierter Präzisions-Drehgeber

Flexibler Adapter zur Kontaktierung von Photonik-Chips in hochauflösenden Drehgebern und Lineargebern.

Die Kontaktierung erfolgt per Thermodenlöten, indem die dünne Flexfahne von der Rückseite aus bis zum Schmelzpunkt erhitzt wird.

Das kompakte Modul enthält weitere optische und elektronische Bauteile und mündet schließlich in einen Miniatur-Stecker.

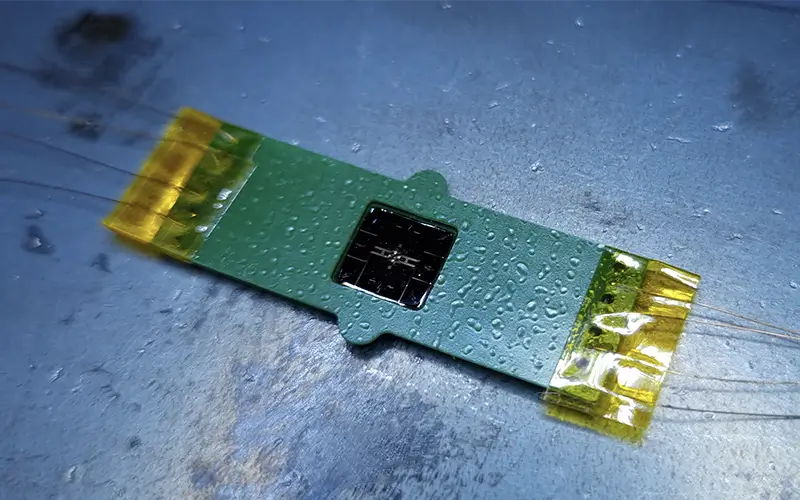

Semiflex-Leiterplatte mit supraleitenden Leiterbahnen

Zur Untersuchung von Quanteneffekten mittels quantenoptischer Methoden. Ziel ist es, die Kontrolle über Bewegungszustände von Quantensystemen zu erreichen. Die Leiterbahnen verlieren ab einer bestimmten Minustemperatur ihren elektrischen Widerstand.

Fertigungsrichtlinien für unsere flexiblen Leiterplatten

Wir fertigen Leiterplatten nach IPC-6013 / IPC-A-600 in folgenden IPC-Klassen:

Bei der Klasse II handelt es sich um die allgemeine Industrieproduktion, also um Geräte, die höheren Anforderungen unterliegen und eine hohe Leistung und eine lange Lebensdauer erfordern.

Elektronik, bei der eine kontinuierliche, unterbrechungsfreie Funktion von entscheidender Bedeutung ist, etwa in der lebenserhaltenden Medizintechnik, in Flugzeugelektronik wie in Flugsteuerungen sowie in sicherheitsrelevanten Anwendungen.

Dokumentation und Rückverfolgbarkeit der gesamten Fertigungskette.

Wir führen folgende Tests durch:

Elektrischer Test nach IPC-9252

Kontrollmessung von Impedanzen (TDR-Verfahren)

Widerstandsmessung

Milliohm-Messung: Vier-Leiter-Methode

Hochvolt-Test bis 500V

EMPB (Erstmusterprüfbericht) mit Vermaßung

Schichtstärkenmessung (X-Ray)

Schliffbildanalyse nach Lötschocktest

Lötbarkeit

Erstellung von CoC (Certificate of Conformity)

Kundenspezifische Prüfungen nach Vereinbarung

Anwendungsspezifische Prüfungen nach Vereinbarung

Lassen Sie sich kostenlos beraten!

Wir helfen Ihnen gerne weiter:

Dr. Christoph Lehnberger

Leiter Technologie

Patrick Peek

Leiter Verkauf

Häufig gestellte Fragen zu flexiblen Leiterplatten

Was sind flexible Leiterplatten?

Flexible Leiterplatten, auch FPC (Flexible Printed Circuit), bestehen aus einer oder meheren dünnen, flexiblen, mit Kupfer kaschierten Folien, als Träger für die Herstellung elektronischer Schaltkreise. Im Gegensatz zu FFCs, bei denen gerade Leiter parallel zwischen zwei Folien einlaminiert werden, können FPCs individuell wie starre Leiterplatten strukturiert und bestückt werden. Mit flexiblen Leiterplatten können Komponenten in dreidimensionalen Konfigurationen platziert werden, was bei begrenztem Platz- und Formfaktor vorteilhaft ist. Das flexible Material Polyimid lässt sich biegen und falten, je nach Biegeradius für den Einbau oder dynamisch bei dauerhafter Bewegung.

Welche Eigenschaften und Vorteile haben flexible Leiterplatten?

- Flexibilität: Sie können in verschiedene Formen gebogen oder gefaltet werden.

- Platzsparend: Durch ihre flexible Natur sind sie ideal für kompakte Elektronik.

- Leicht und dünn: Sie bieten eine geringere Masse im Vergleich zu starren Leiterplatten.

- Vibrationsbeständig: Sie widerstehen mechanischen Beanspruchungen und sind widerstandsfähiger gegen Vibrationen.

- Reduzierte Verbindungspunkte: Weniger Lötstellen verringern mögliche Ausfallstellen und verbessern die Zuverlässigkeit.

Wofür werden flexible Leiterplatten verwendet?

- Medizinische Geräte: Implantierbare und tragbare Geräte benötigen flexible Lösungen.

- Automobilindustrie: Für Sensoren, Steuergeräte oder Displays, die oft unter beengten Platzverhältnissen arbeiten.

- Elektronikgeräte: Mobiltelefone, Tablets und Wearables profitieren von der Platzersparnis.

- Luft- und Raumfahrt: Flexibilität und Leichtbau sind in diesen Bereichen besonders wichtig.

- Industrieelektronik: Maschinensteuerungen und Roboter, wo Beweglichkeit und Anpassbarkeit gefragt sind.

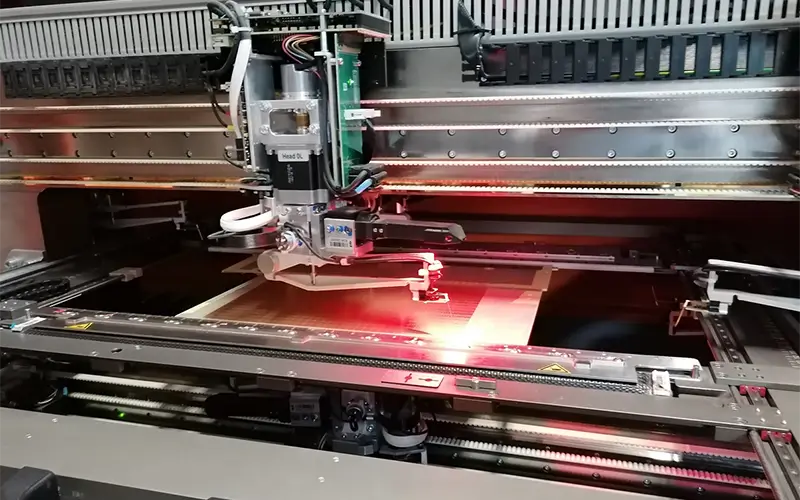

Wie werden flexible Leiterplatten hergestellt?

- Substratmaterial: Verwendung flexibler Materialien wie Polyimid oder Polyester.

- Ätzen der Leiterbahnen: Kupfer wird auf das Substrat aufgebracht und in das gewünschte Layout geätzt.

- Laminierung: Schutzschichten werden hinzugefügt, um die Kupferleiter zu isolieren.

- Löcher bohren und Komponenten montieren: Durchkontaktierungen und Bauelemente werden aufgebracht.

- Testen: Jedes PCB wird auf Funktionsfähigkeit und Defekte geprüft.

Worauf muss man bei der Herstellung achten?

- Design-Layout: Flex-PCBs erfordern spezielle Designregeln, um Biegeradien und mechanische Belastungen zu berücksichtigen.

- Materialwahl: Es müssen Materialien verwendet werden, die nicht nur flexibel, sondern auch hitzebeständig und elektrisch isolierend sind.

- Lötprozesse: Es muss sichergestellt werden, dass das flexible Material bei hohen Temperaturen nicht beschädigt wird.

- Haltbarkeit: Wiederholtes Biegen kann auf Dauer zu mechanischen Belastungen führen, die berücksichtigt werden müssen.